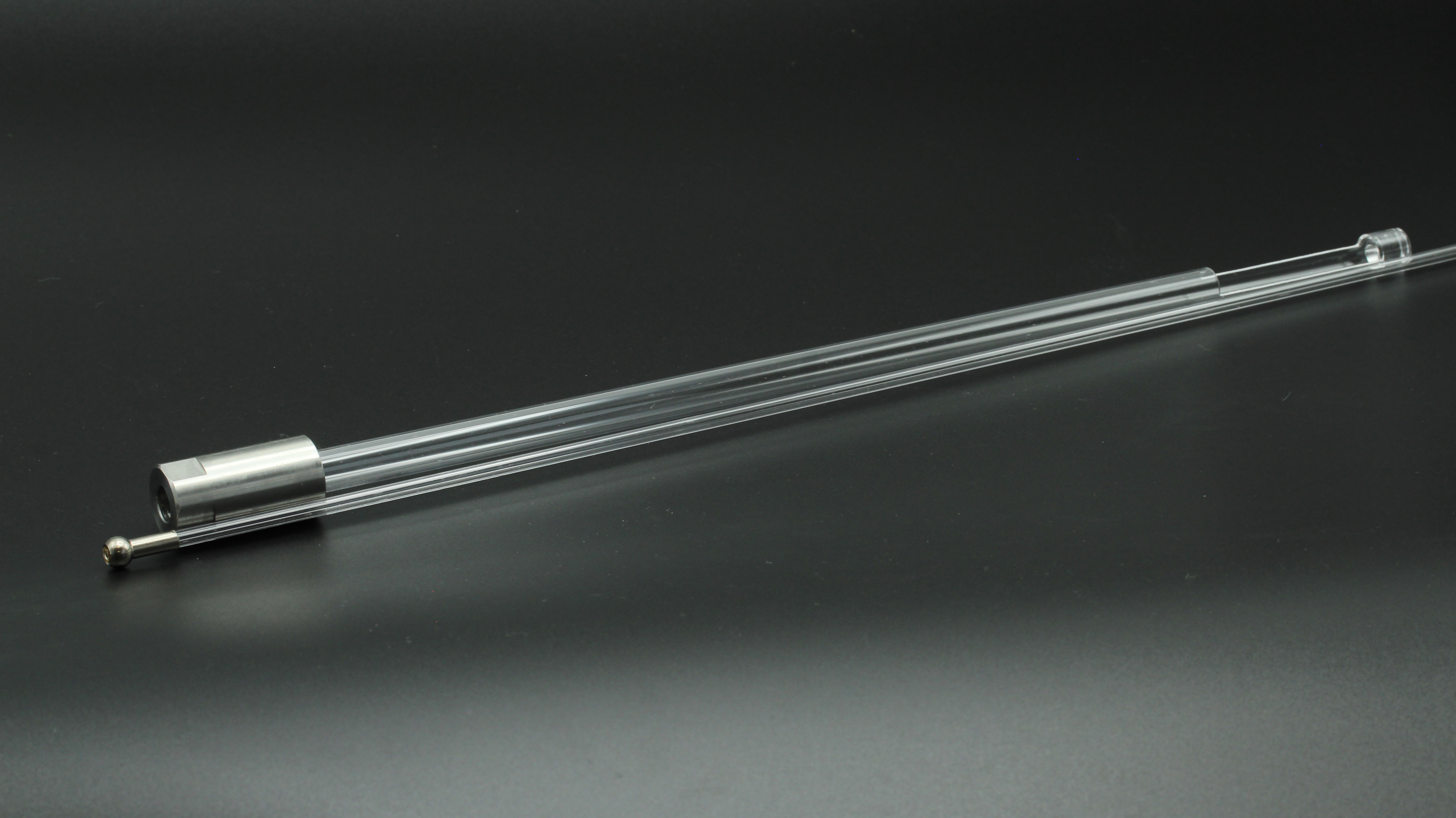

DIL L76

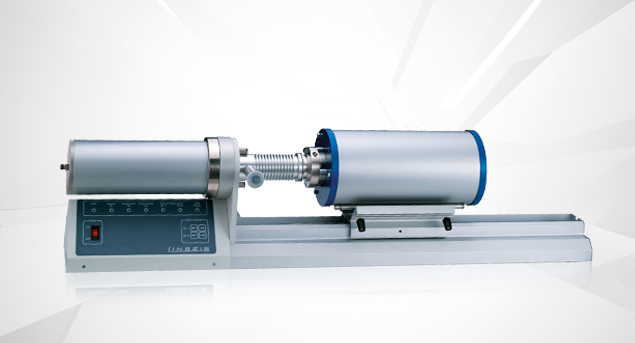

Robust Economy Horizontal Dilatometer

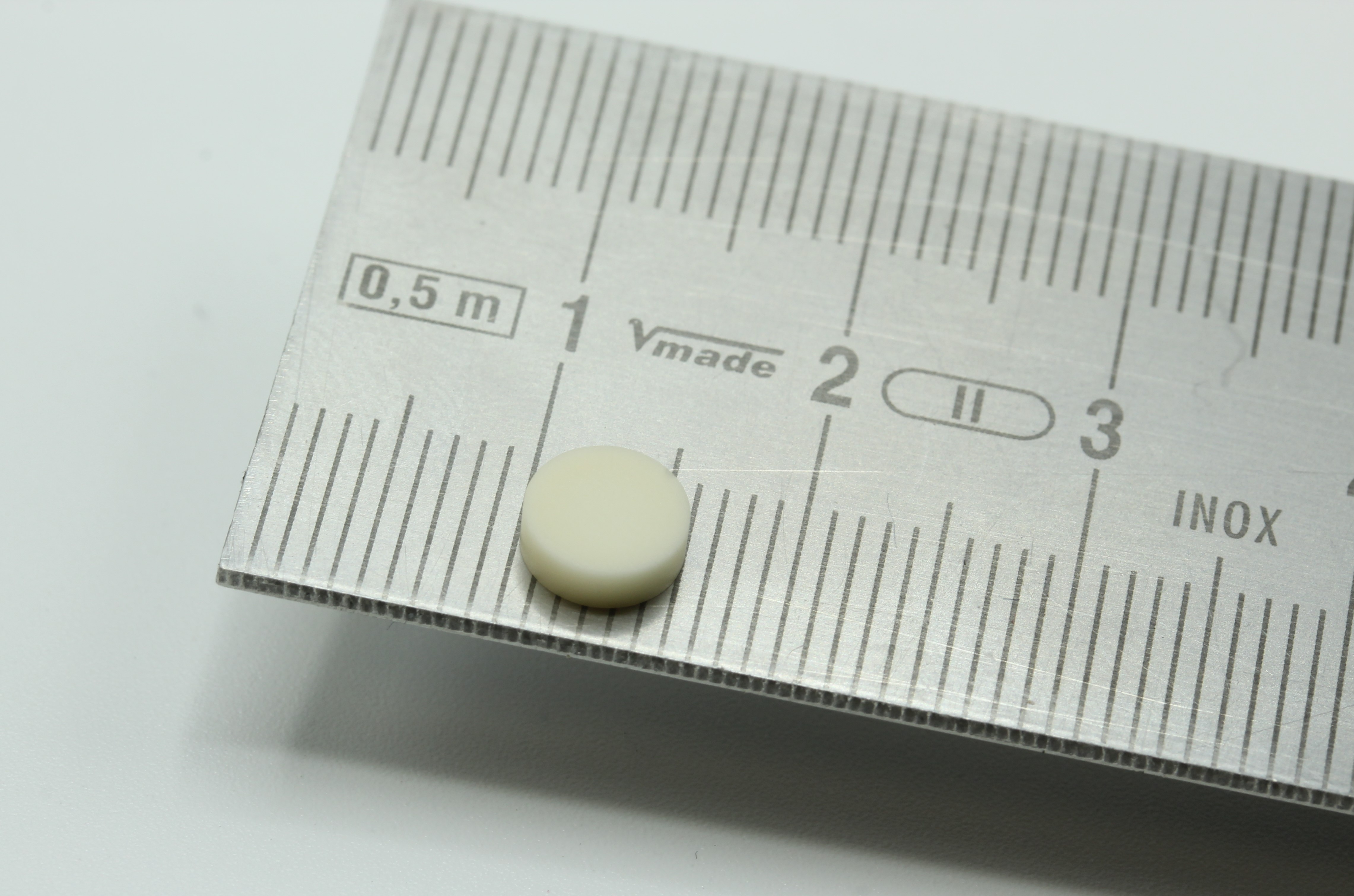

The main application field for the LINSEIS DIL L76 Dilatometer series is the CTE measurement of ceramics, brick, tile, porcelain and building materials. Furthermore it is widely used for quality control purposes in ceramics and in metal industries.

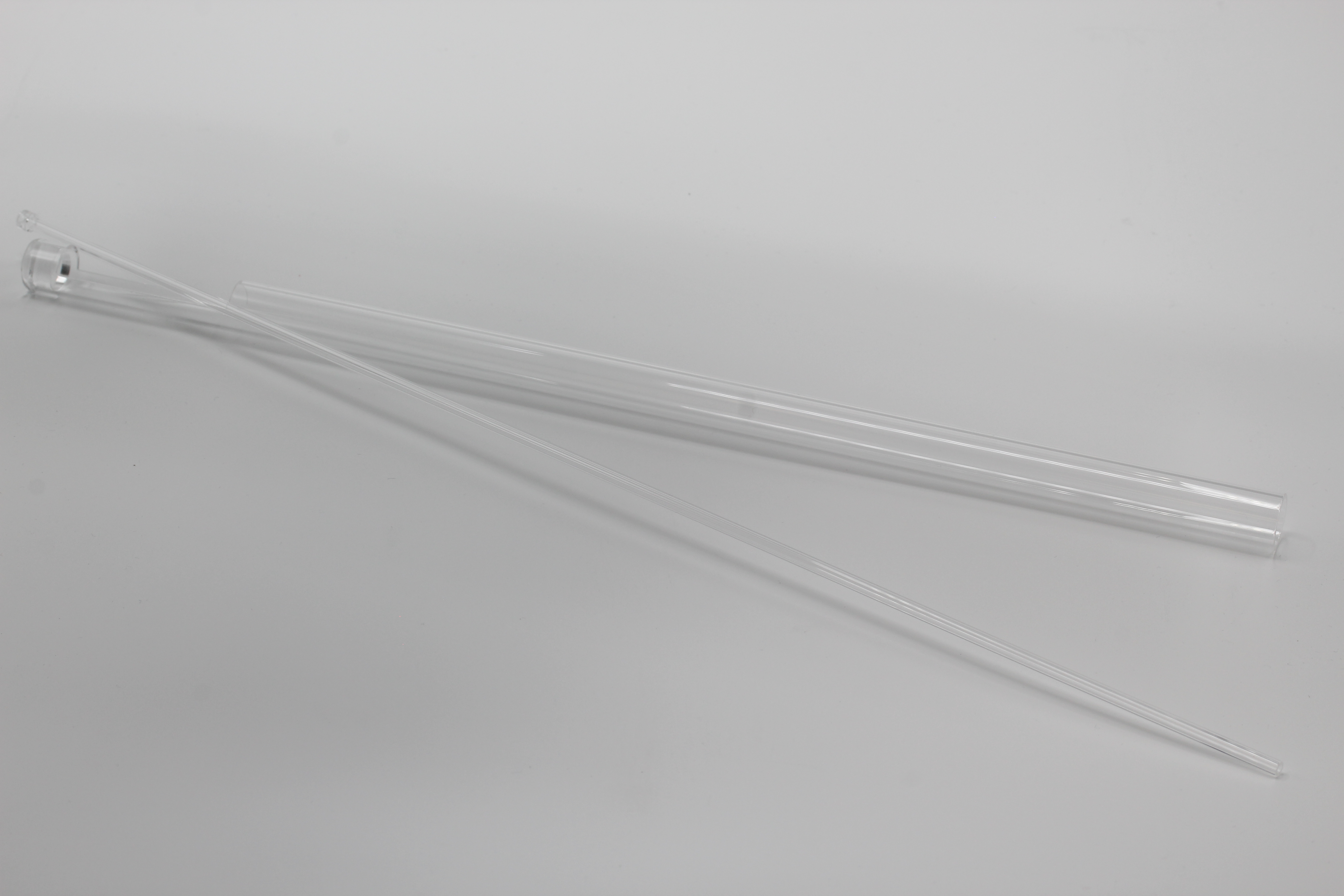

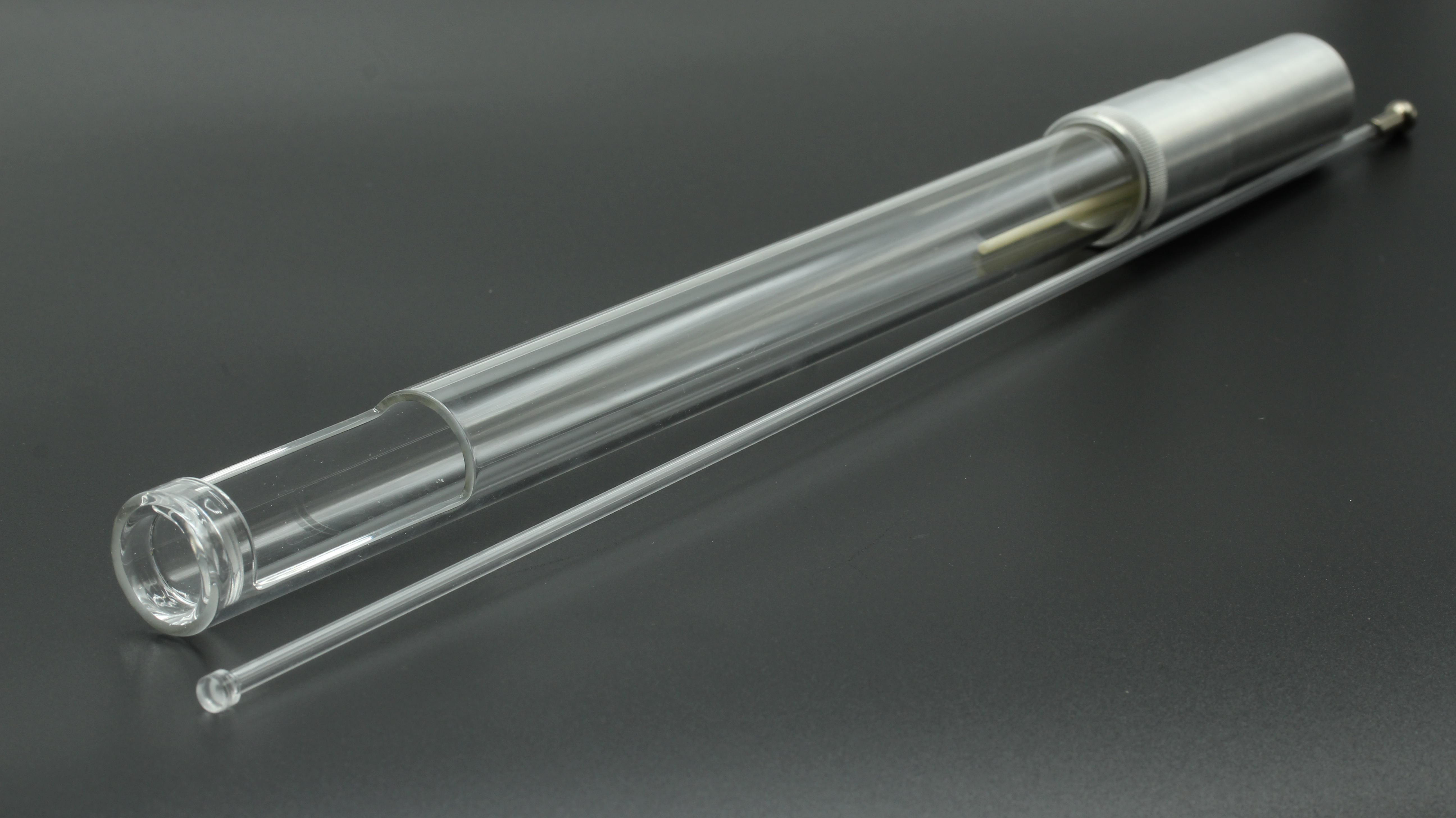

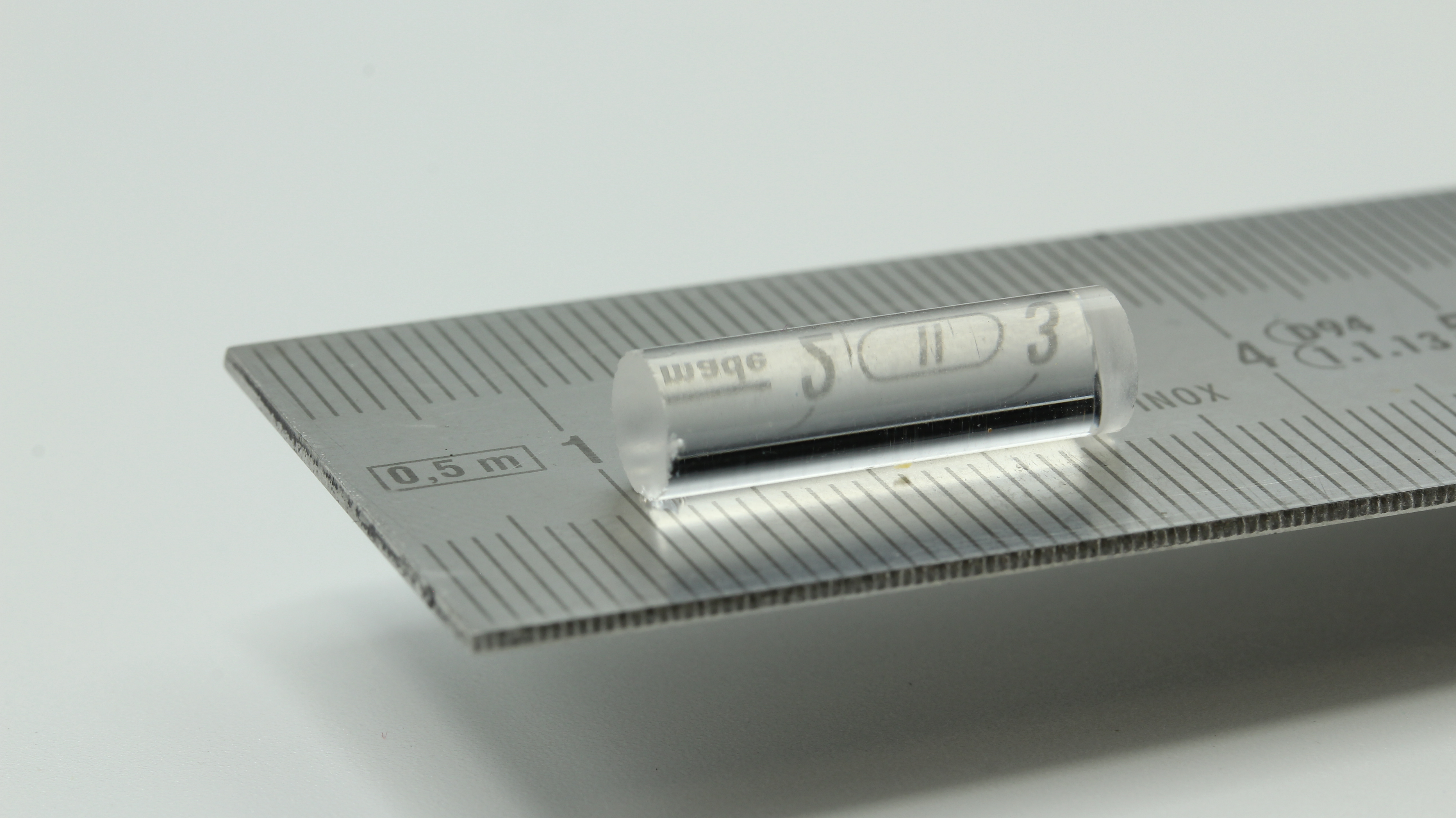

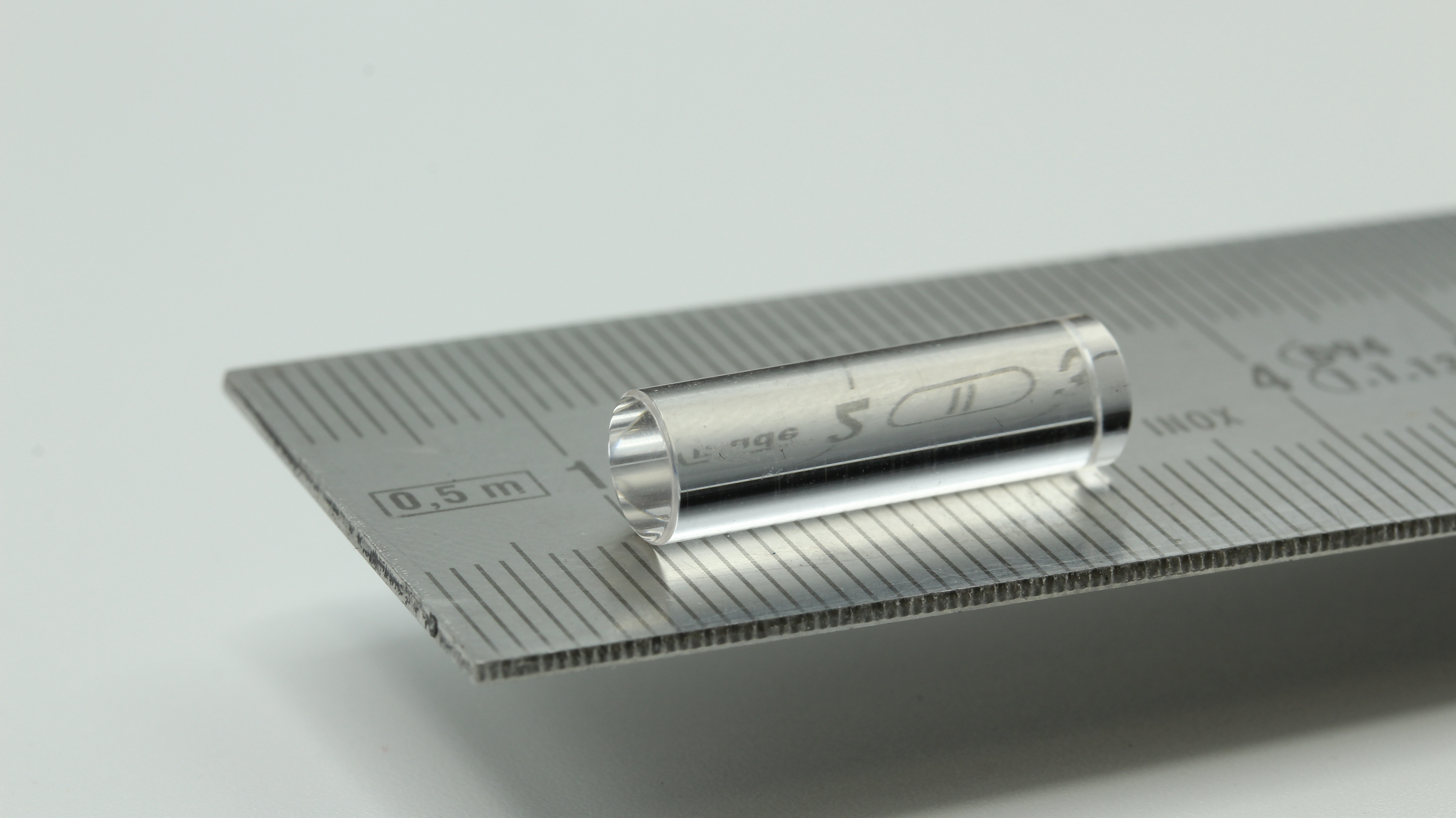

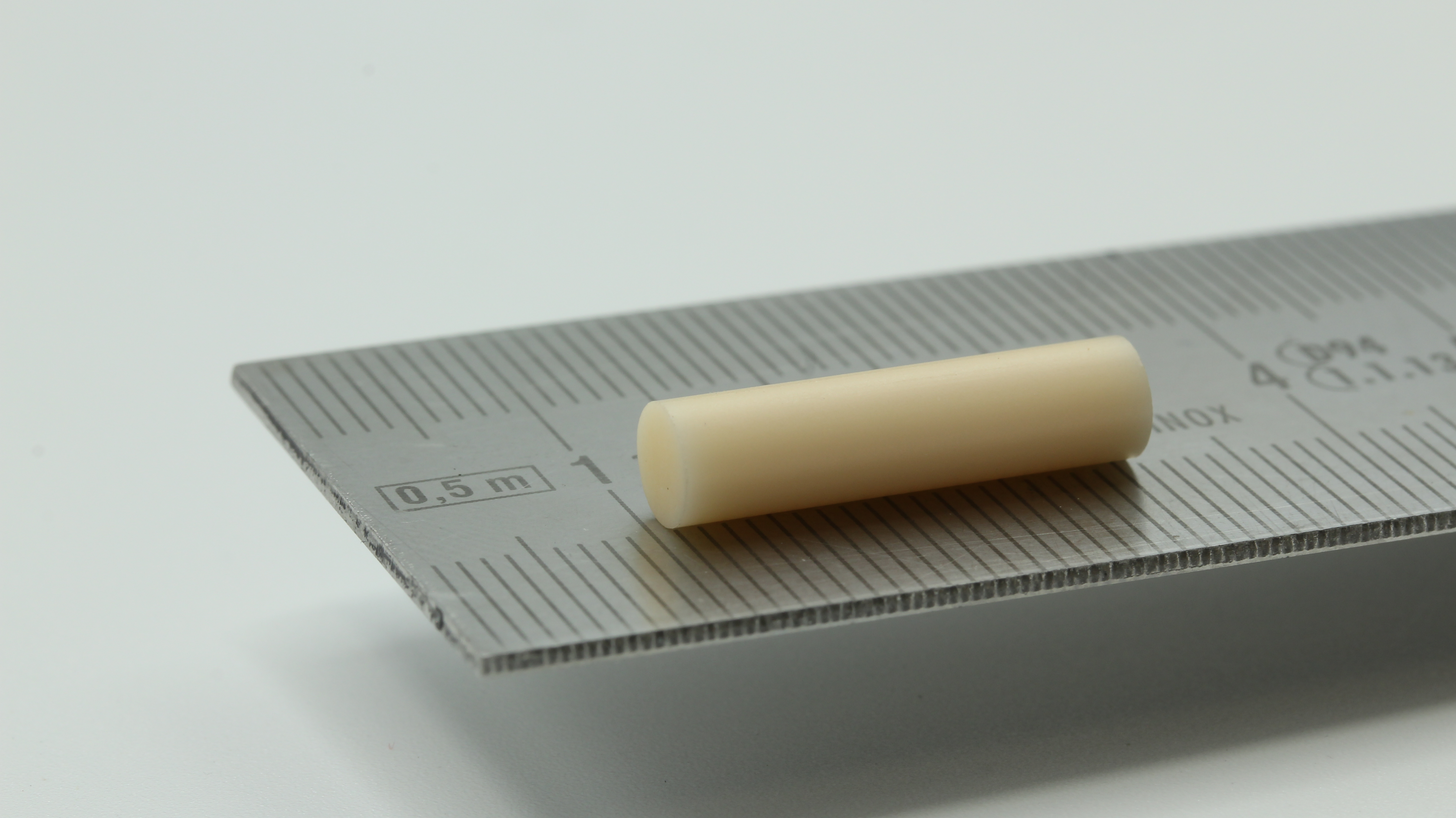

Thanks to the fact we started to develop and build Dilatometers in the year 1955, this instrument is very reliable and covers a wide temperature range from RT up to 1000°C, 1400°C and 1600°C with user exchangeable furnaces. It consists of measurement systems made out of quartz glass (up to 1100°C) and Al2O3 (up to 1600°C).

The sensor is a highest precision LVDT (linear variable differential transformer), which has an indefinite resolution. Together with the 32 Bit software package LINSEIS WIN-TA / WIN-DIL, the Dilatometer provides an excellent solution for standard quality control type CTE measurements.

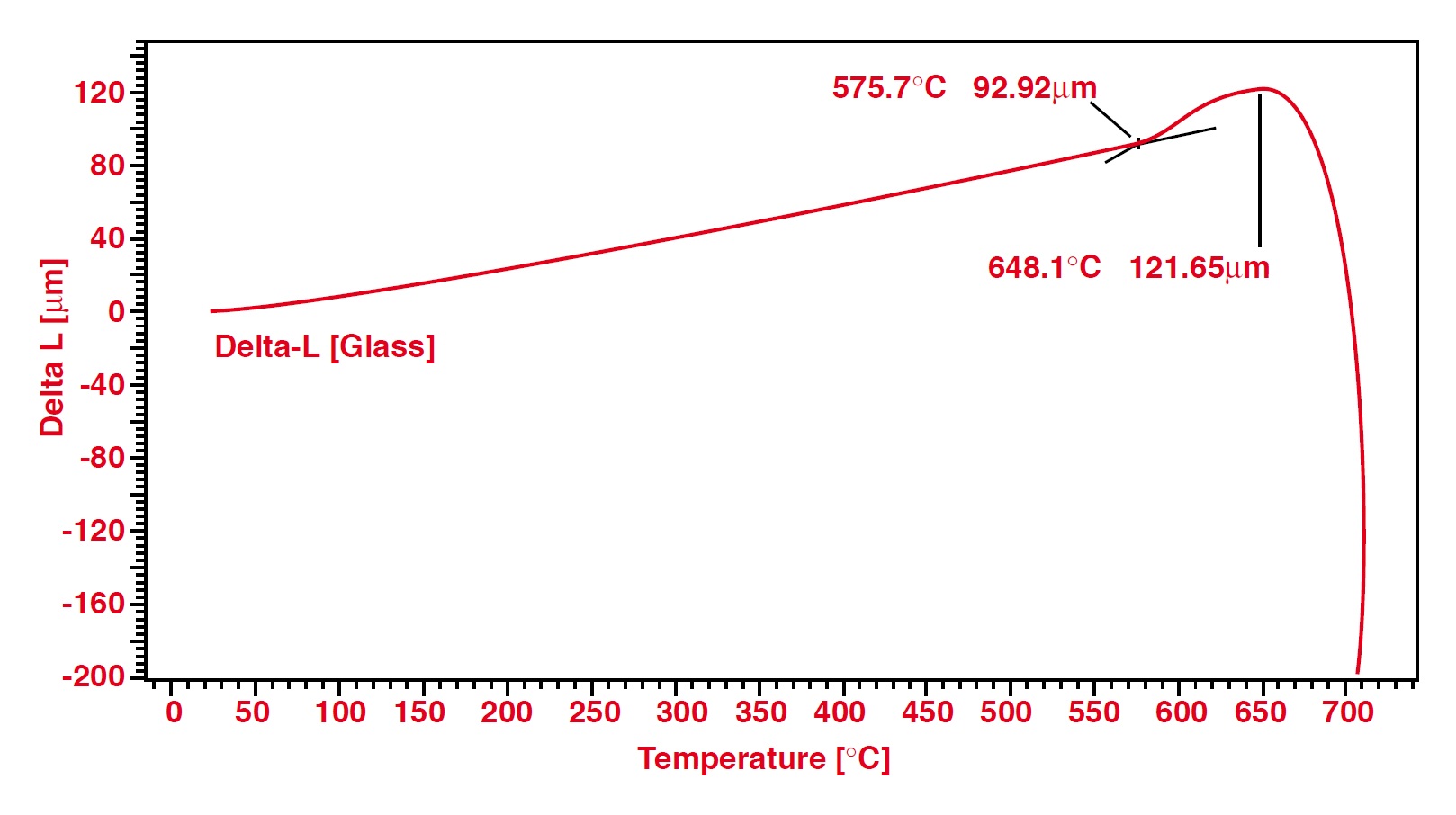

The following physical properties can be measured with the instrument: CTE, linear thermal expansion, Alpha Physical, sintering temperature, phase transformations, softening points, decomposition temperatures, glass transition temperatures.

You are interested in a DIL L76?

You need more information?

Contact our application experts!

Send request

Specifications

Modell | DIL L76 |

Temperature range: | RT up to 1000°C |

LVDT: | |

Delta L resolution: | 0,05 nm |

Measuring range: | +/- 2500 µm |

Contact force: | 50 mN up to 1N |

Optical Encoder: | |

Delta L resolution: | 1 nm |

Measuring range: | +/- 25000 µm |

Automatic sample length detection: | yes |

Force modulation: | no |

Contact force: | 50 mN up to 1N |

Multiple furnace configuration: | optional |

Motorized furnace operation: | optional |

Gas dosing: | manual gas dosing or mass flow controller 1/3 or more gases |

Contact force adjustment: | - |

Single/double dilatometer: | - |

Softening point detection: | included |

Density determination: | optional |

L-DTA: | optional |

Rate Controlled Sintering (RCS): | optional |

Thermal library: | optional |

Electric thermostatization of measuring head: | included |

Low temperature options: | LN2 |

Vacuum tight design: | - |

Automatic evacuation system: | - |

OGS Oxygen Getter System: | - |

Software

General Features

- Program capable of text editing

- Data security in case of power failure

- Thermocouple break protection

- Repetition measurements with minimum parameter input

- Evaluation of current measurement

- Curve comparison up to 32 curves

- Storage and export of evaluations

- Export and import of data ASCII

- Data export to MS Excel

- Multi-methods analysis (DSC TG, TMA, DIL, etc.)

- Zoom function

- 1 and 2 derivation

- Programmable gas control

- Statistical evaluation package

- Free scaling

DIL-Features

- Glass transition and softening point evaluation

- Softening point detection with automatic software controlled system shut down

- Display of relative/absolute shrinkage or expansion curves

- Presentation and calculation of technical / physical expansion coefficient

- Rate Controlled Sintering (RCS) Software

- Sinter process evaluation

- Semiautomatic evaluation functions

- Several system correction features

- Automatic zero point adjustment

- Automatic software controlled sample pressure adjustment

Applications