THB Basic

Unsurpassed measurement accuracy

€12,622.50*

% €14,850.00* (15% saved)Available, delivery time: 3-4 weeks

This measuring instrument simultaneously delivers the three material properties thermal conductivity, thermal diffusivity and specific heat after just a few minutes, regardless of whether you have placed the corresponding sensors in bulk solids, gels, pastes or plates or immersed them in liquids.

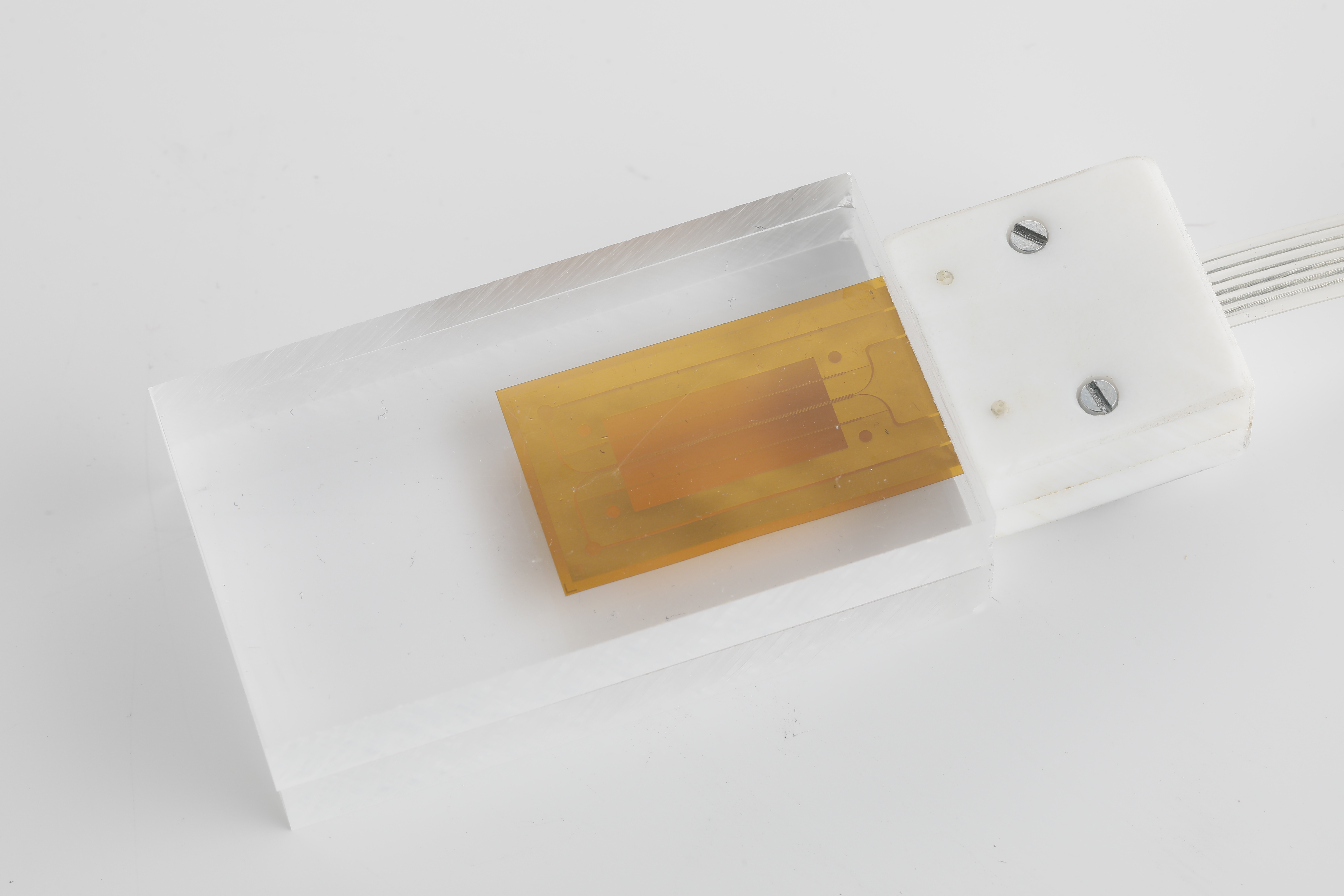

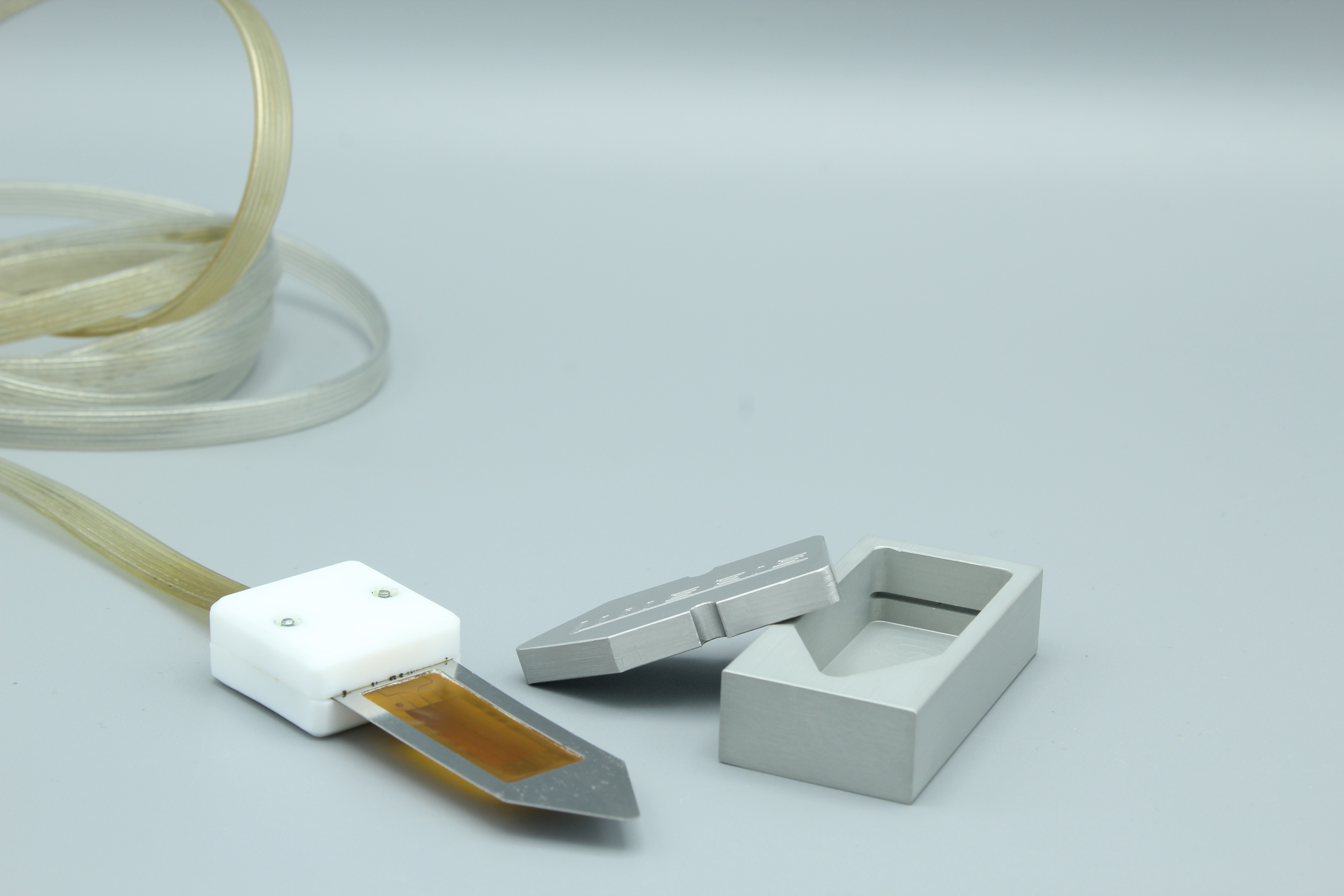

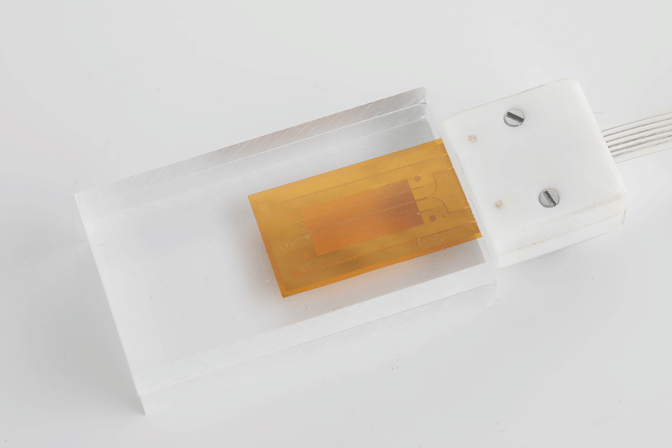

Sample preparation of solids is as simple as it is straightforward. One plane contact surface of each of two sample halves is sufficient for the sensor. Calibration is very simple and does not need to be performed before each measurement.

The THB measures absolute values with an accuracy that does not lag behind conventional plate or LaserFlash devices.

Complies to the following Norms: ASTM D 5930-01, DIN ISO 2200-2, ASTM D 5334.

Advantages at a glance:

Unsurpassed measurement accuracy for determining thermal conductivity

- One-button solution:

- Automated measurement mode

- No specialist personnel required to operate the instrument

- No erroneous measurements due to incorrect measurement parameter input

- Thermal conductivity AND thermal diffusivity

- Measurement of thermal diffusivity with very low measurement uncertainties

- Calorimeter function: Calculation of specific heat capacity

Measurements within seconds

Non-destructive measurements with half-shell sensor

Compact dimensions

THB Basic: small and light

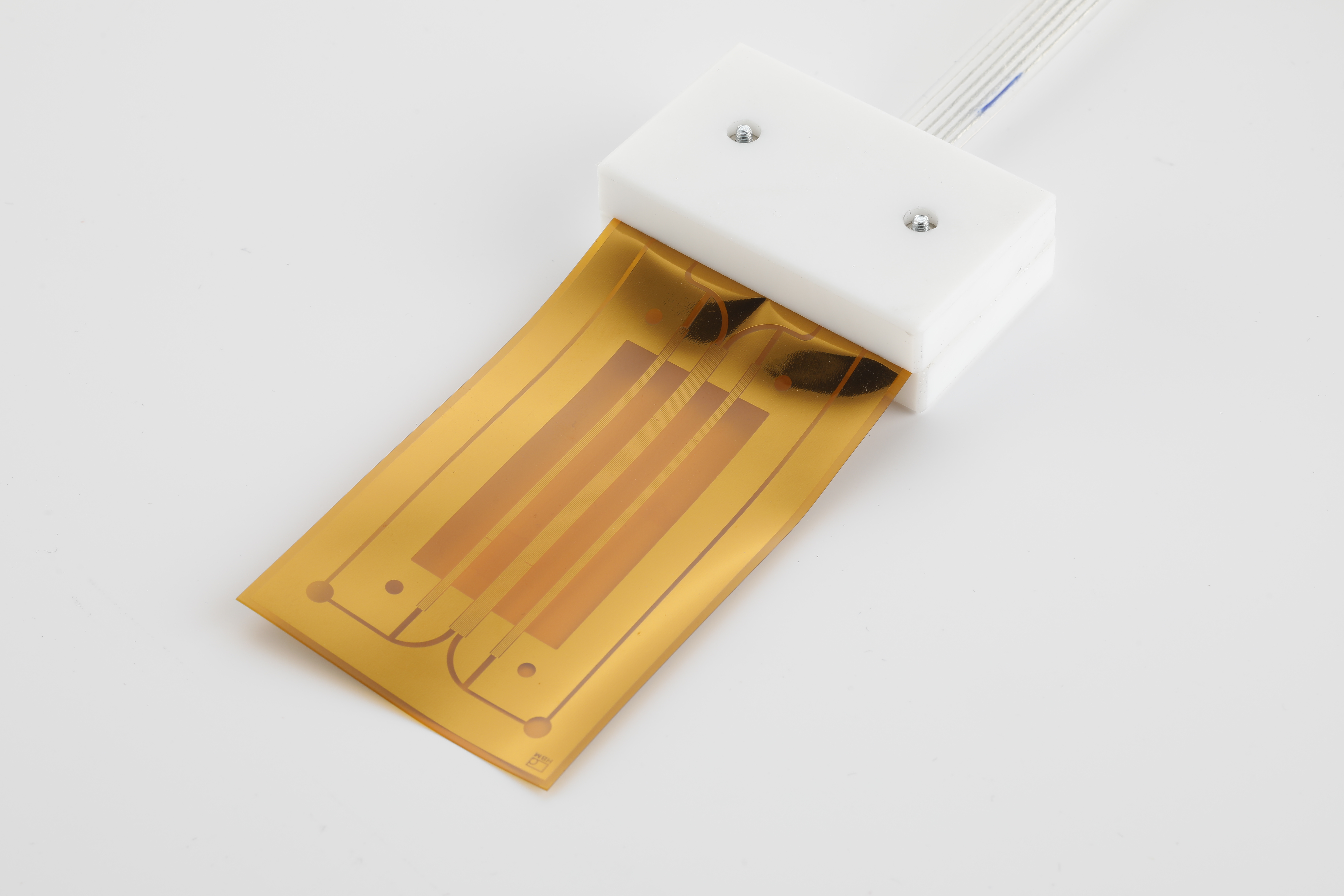

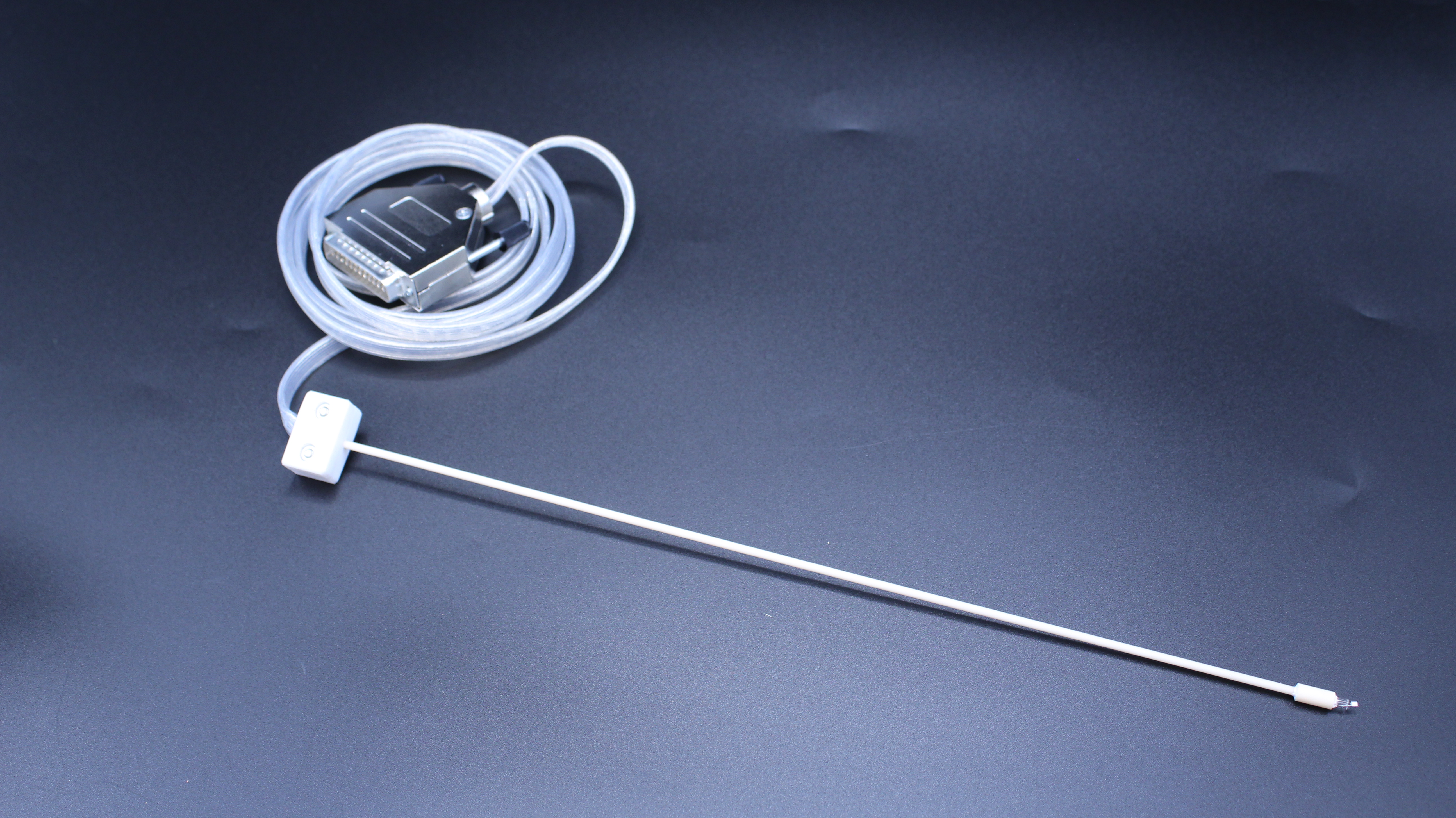

Different sensors for your application

THB Basic

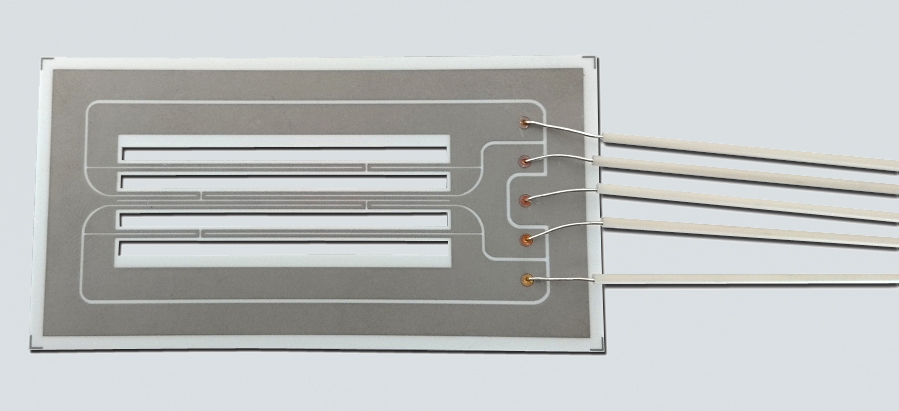

- THB/B sensor included (THB/A sensor on request) and PMMA calibration material

- suitable for materials with low thermal conductivity (insulation and building materials)

- easy installation - basic installation of the measuring device is done remotely

You are interested in a THB Basic?

You need more information?

Contact our application experts!

Specifications

Model | THB Basic |

Measuring range: | |

Thermal conductivity: | 0,01 up to 5 W/(mK) |

Thermal diffusivity: | 0,05 up to 50 mm2/s |

Specific heat capacity: | 100 up to 5000 kJ/(m3K) |

Measurement precision: | |

Thermal conductivity**: | better than 1 % |

Thermal diffusivity**: | better than 4 % |

Thermal capacity**: | better than 4 % |

Measuring duration: | |

Solids: | approx. 1 up to 10 min |

Liquids: | approx. 1 up to 120 s |

Operating temperature: | |

Sensor: | –150°C up to 700°C |

Sensor type: | Kapton, Ceramics |

Sample size: | |

Smalest sample size*: | 1.5 x 1.5 x 2 mm |

Maximum sample size: | unlimited |

* depending on furnace and sensor, sample size depends on material

** depending on sample sensor and sample preparation

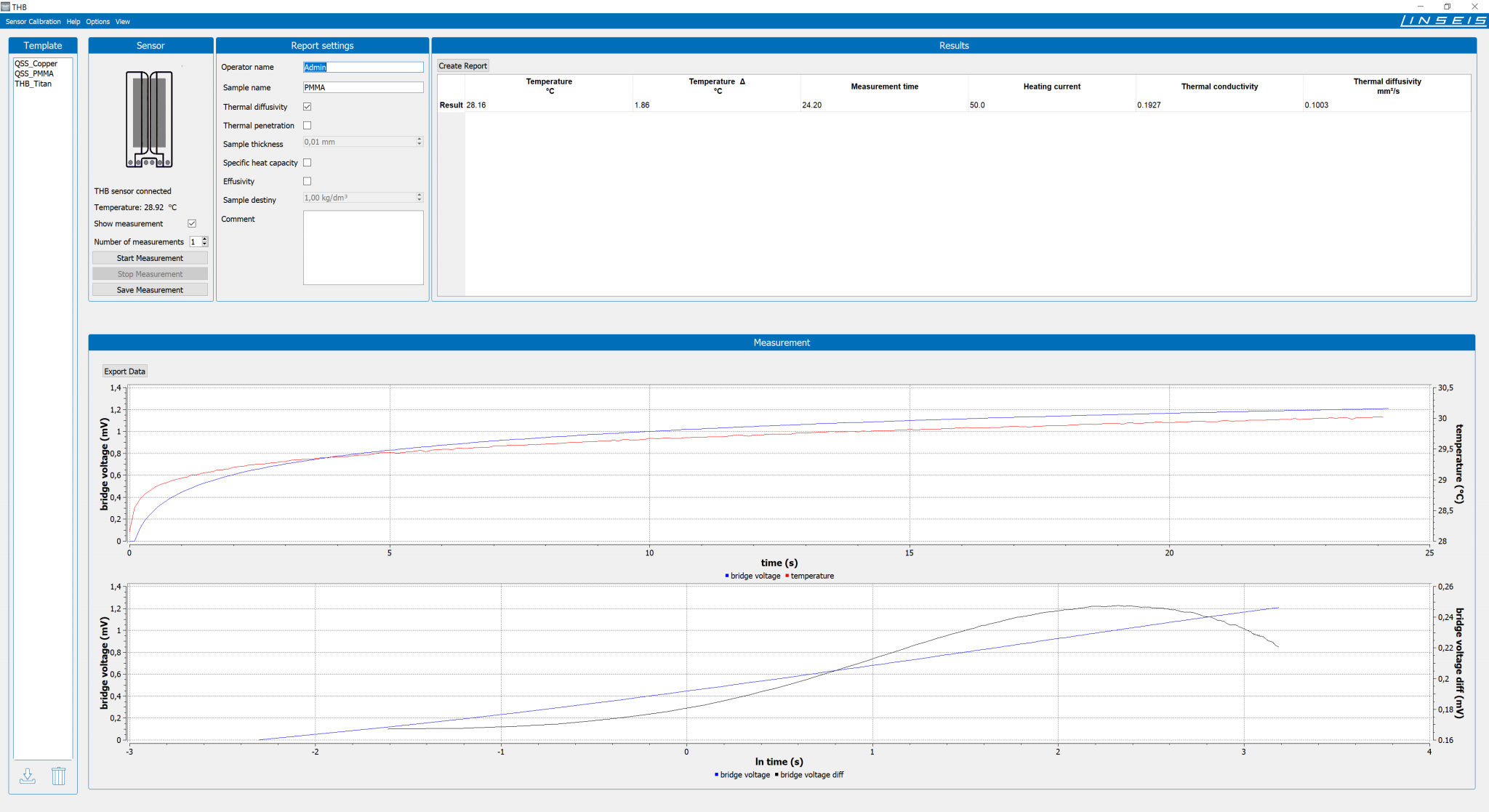

Software

Advantages at a glance

- Advanced THB Windows®-based software interface

- Provides the fastest measurement times

- No possibility for application errors thanks to optimized, software-controlled measurement algorithms

- Enables most accurate and time-saving measurements

- One-button solution: results at the touch of a button

- Easy data export to Microsoft Excel®

Applications

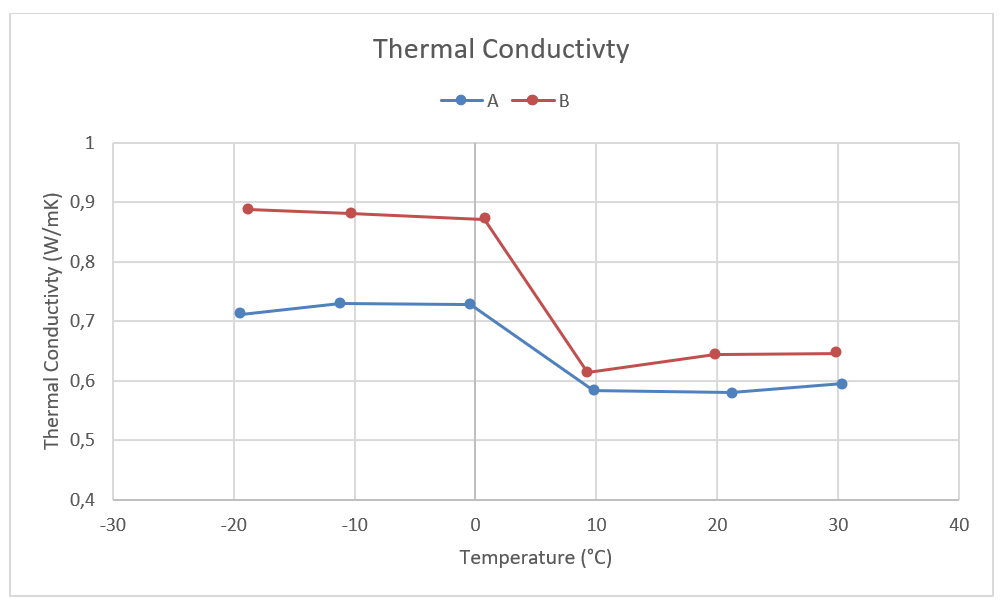

Application: THB Basic/Advance – Phase change material – Thermal conductivity

The thermal conductivity of Sample A slightly increases with heating up to 0 °C, whereas Sample B shows slightly decreasing values. Both samples change from the solid to the liquid state in the temperature range from 0 °C to 10 °C which can also be clearly seen in the thermal conductivity drop. With increasing temperature, the thermal conductivity of both samples increases slightly. In general, Sample B shows higher thermal conductivities compared to Sample A.

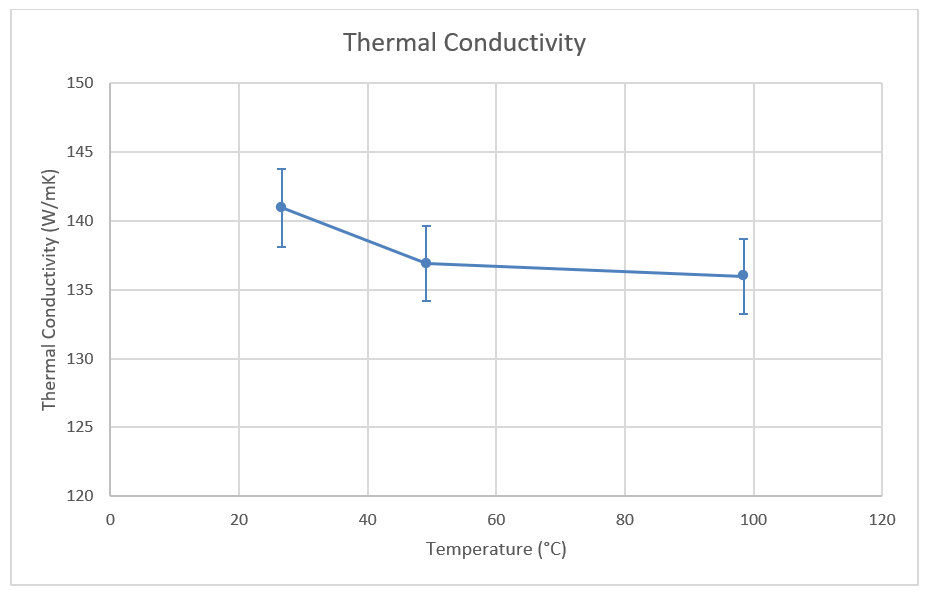

Application: THB Advance – Aluminium Alloy – Thermal conductivity

The thermal conductivity of an aluminium alloy was investigated from room temperature to 100 °C using the THB. For the measurement the QSS sensor was placed between two sample pieces and pressed together for an improved thermal contact. The configuration was placed in a furnace and the temperature steps were room temperature, 50 °C and 100 °C. At each step the measurement was repeated three times and the results were averaged. In the diagram one can see that the thermal conductivity is slightly decreasing with temperature. The error bars show an uncertainty of 2 %.