Dilatometer – DIL

Expansion Measurement / Sintering processes / Contact angle

Linseis produces a wide range of single, dual, differential, quattro, quenching, laser and optical dilatometers in a temperature range from -263 °C to 2800 °C and a resolution down to 0.3 nm. Thanks to our long experience (since 1953), Linseis offers dilatometers with unsurpassed performance.

Dilatometers are widely used for research and development as well as for quality control of solids, liquids, powders and pastes to determine:

- Determination of coefficient of thermal expansion (CTE)

- linear thermal expansion (ΔL)

- sintering temperatures and sintering steps

- determination of the glass transition (Tg)

- phase change

- optimization of firing processes

- Volume changes

- Rate Controlled Sintering (RCS)

- Decomposition

- Density change

Dilatometry (DIL) is a technique in which a dimension of a substance is measured under negligible sample loading as a function of temperature (e.g., measurement of expansion or measurement of shrinkage) while the substance is subjected to a controlled temperature program in a specified atmosphere.

Products

of Expansion Measurement / Sintering processes / Contact angle

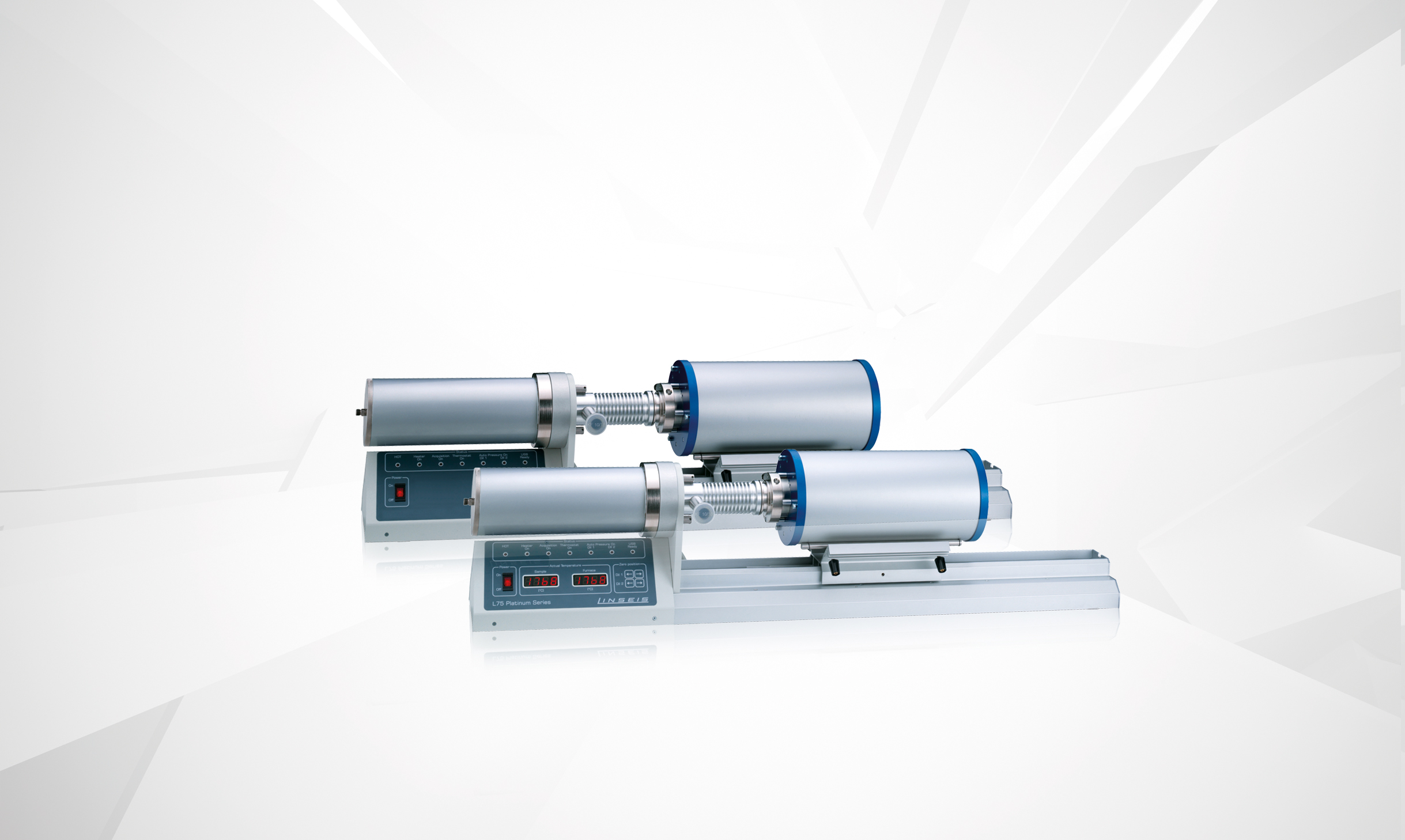

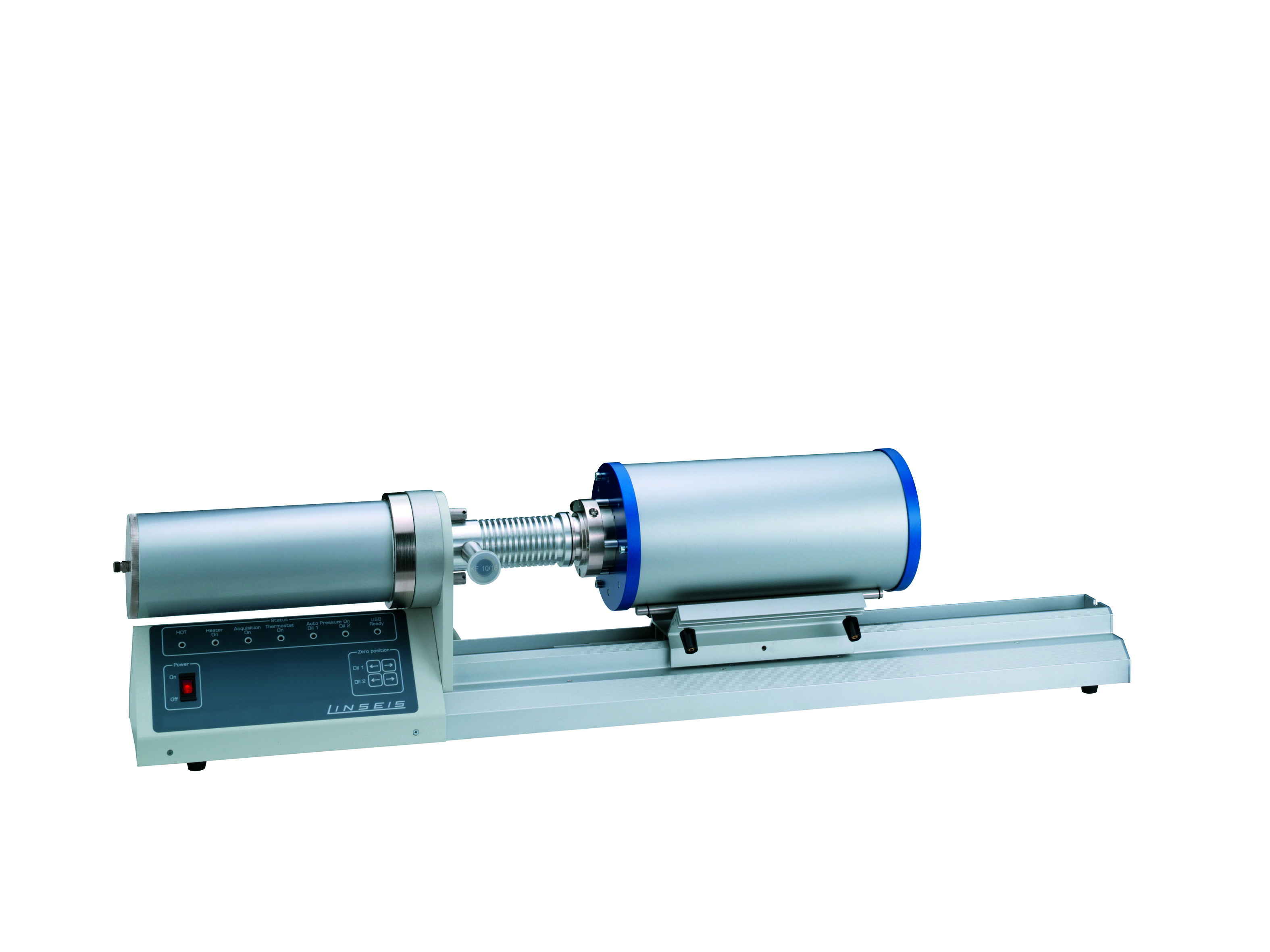

Horizontal arrangement

- Easy and robust design at a modest price

- Perfect choice for mid temperature range

- Easy sample handling

- Customized dilatometers for huge samples available

Vertical arrangement

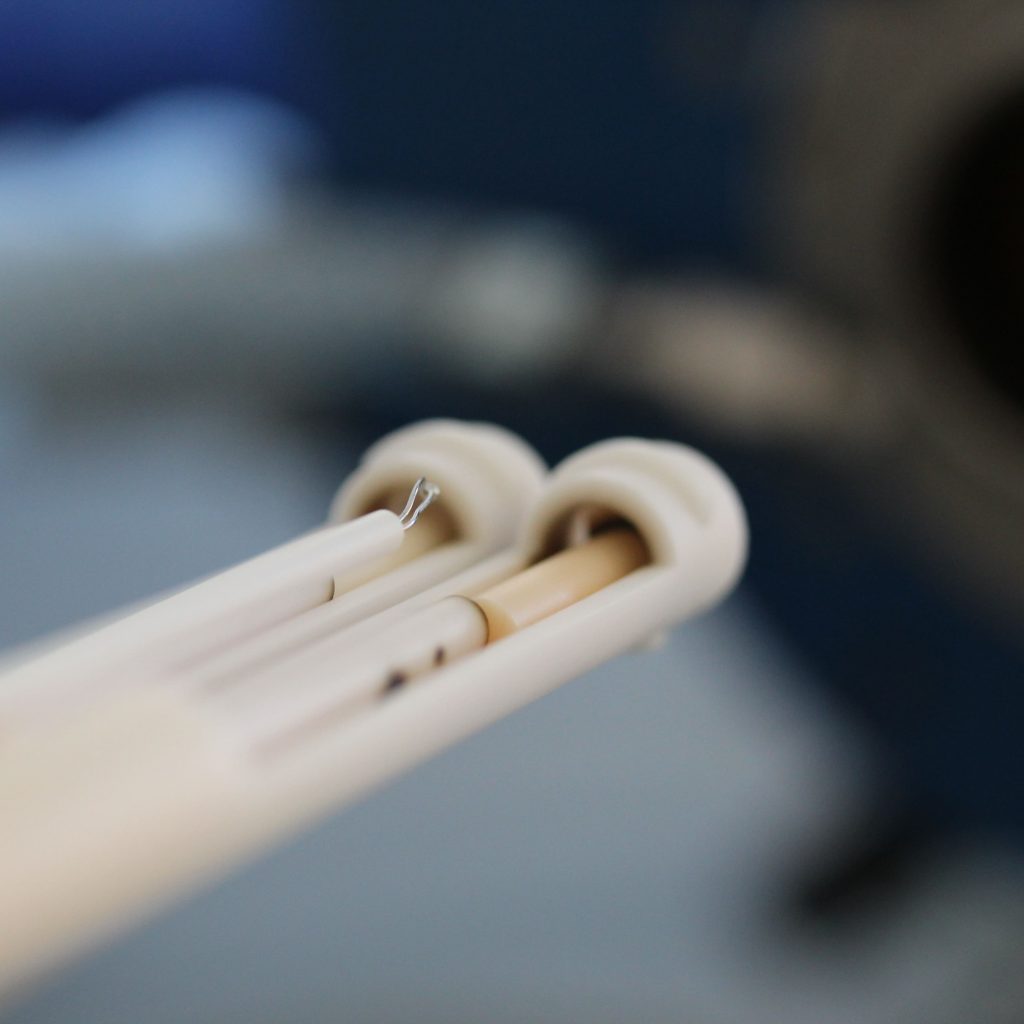

- Zero friction design (the specimen is in contact only with the end stop and the push rod).

- Multiple furnace arrangement (up to three furnaces):

- - to cover the whole temperature range from -180 to 2800°C, especially ideal for low and very high temperatures

- - to avoid convection

- Perfect for low temperature measurements (furnace at the bottom - measuring compartment at the top) to ensure access to the gas, cold air (falling down) under the sensor area

- Perfect for high temperature measurements (furnace on top - measuring compartment on bottom) to ensure access to the gas, hot air (flows upwards) above the sensor area

- Small footprint and low requirements for laboratory space

- Available as single, differential/double and quattro arrangement (1, 2 or 4 samples simultaneously)

Horizontal Design